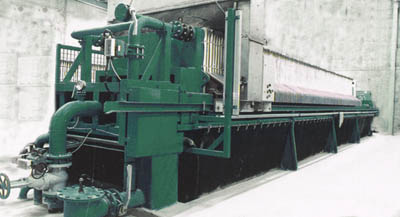

The use of ECOFILTER® in thickening on filter presses and belt filter presses optimizes the capacities of your installation and eliminates clogging of the supporting cloths.

ECOFILTER® improves the preparation of the sludge and increases their dewatering capability by acting as a structuring agent.

APPLICATIONS :

Sewage

Sludges in following industries :

food mining and quarrying ceramics and paint

carboard glass chemicals and tanneries

surface treatment metallurgy

ECOFILTER® as a filter aid, is mixed directly with the sludge to be dewatered, preferably before or during the flocculation or coagulation stage. The mixing is performed at a rate of 5 to 15 % in weight according to the concentration of products to be treated.

ADVANTAGES :

- Improvement in the behaviour of the sludge on the filter cloth.

- Increase in the pressure and the filtration rate

- Reduction in sludge creep and less cleaning needed.

- Improvement in dryness and in the action of the flocculant and/or coagulant.

- Increase in the agronomic and energy content of the sludge.

- Overall reduction in the costs of filtration.

10, avenue des Verriers 02 600 Villers Cotterêts

Tél: 06 52 70 41 57 - mail: sales@sowood.co